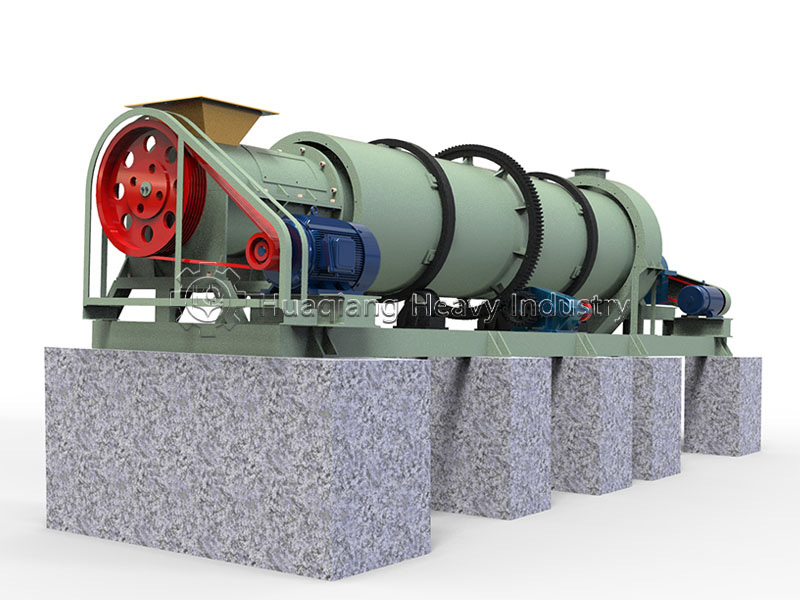

New Type Organic Fertilizer Granulator

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

New Type Organic Fertilizer Granulator

The agitator granulator utilizes high-speed rotating agitator teeth to produce granules. Its unique agitation and granulation method has distinguished it in the field of granule production. Its core operating principle is to feed the mixed material into the granulation drum, where the high-speed rotating agitator teeth vigorously stir, impact, and tumble the material. This causes the material to gradually agglomerate into granules due to friction, centrifugal force, and its own viscosity.

This granulation method does not require complex extrusion equipment and can meet the granulation needs of a variety of materials. It is particularly suitable for materials with high viscosity or containing certain fibers. Compared with other granulation equipment, the agitator granulator has a gentle granulation process, causes less damage to the material, and produces granules with good roundness and uniform size, making it suitable for small and medium-sized granulation production.

Scope Of Application

Fertilizer field: It can produce organic fertilizer, bio-organic fertilizer, compound microbial fertilizer, etc. It can ferment organic waste such as livestock and poultry manure, straw, mushroom residue, etc. into granular fertilizer, solving the problem of easy agglomeration and poor fluidity of organic fertilizer.

It excels in biofertilizer granulation, as the gentle granulation process effectively preserves the activity of the bacteria and ensures the effectiveness of the biofertilizer. It can also produce a variety of medium and trace element fertilizers to meet the specific nutrient requirements of different crops.

Chemical industry: Suitable for granulation of various viscous chemical raw materials, such as dyes, pigments, catalysts, etc., through granulation, these chemical products have better performance and storage stability.

Pharmaceutical industry: It can be used for the granulation of some traditional Chinese medicine granules and pharmaceutical excipients. The granulation process can reduce the loss of drug ingredients and ensure the quality of drugs.

Feed industry: It can mix various feed raw materials and granulate them to produce pellet feed suitable for livestock, poultry, aquatic products, etc., and improve the palatability and digestibility of feed.

Equipment Structure And Composition

Feeding device: It consists of a hopper and a screw feeder. The hopper is used to temporarily store the material to be granulated. Its capacity depends on the production scale and is generally 0.5-3 cubic meters.The screw feeder controls the speed through a variable frequency motor to feed the material into the granulation drum evenly and stably, ensuring that the feed amount matches the granulation speed and providing a guarantee for uniform granulation.

Granulating cylinder: It is the main working part of the agitator granulator. It is usually cylindrical and made of stainless steel with good corrosion resistance and wear resistance.The diameter and length of the granulating cylinder are determined by production capacity, generally 0.5-2 meters in diameter and 1-3 meters in length. Its inner wall is smooth to reduce material adhesion and wear.

Stirring teeth: Installed on the rotating shaft inside the granulating cylinder, it is the core component of the granulating process. There are usually 4-8 stirring teeth, which are symmetrically distributed. The stirring teeth are made of high-strength alloy steel and have high hardness and wear resistance after heat treatment.The shapes of stirring teeth are various, the most common ones are paddle type, claw type, etc. Their length and angle are optimized to enhance the stirring, impact and turning effects on the material, and promote the agglomeration of the material into particles.

Drivetrain: It consists of a motor, a reducer, a coupling, etc. The motor provides power, and the power depends on the equipment model, generally 5.5-30kW.The reducer converts the high-speed rotation of the motor into an appropriate speed for the stirring teeth. The speed of the stirring teeth is usually 300-1000 rpm. The power is transmitted to the stirring shaft through the coupling to ensure the stable rotation of the stirring teeth.

Water spray device: It consists of a water pipe and a nozzle, installed on the upper part of the granulating cylinder, and is used to spray an appropriate amount of water or binder onto the material in the granulating cylinder.The number and position of the nozzles can be set according to the size of the granulating cylinder to ensure that the material can be evenly wetted and promote the formation and stability of the particles.

Discharging device: Located at the end of the granulation drum, this is usually an inclined chute that transports the granules to the subsequent process. The chute is made of stainless steel to prevent material from sticking and ensure smooth discharge.

Working Principle

Raw material pretreatment: Organic fertilizer raw materials must first be fermented and composted. The fermented material is then crushed and screened to a particle size of 40-80 mesh to ensure granulation. The moisture content of the material is also controlled between 20% and 30%. If the moisture content is too high, it needs to be air-dried or dried; if it is too low, water should be added.For compound fertilizers, basic fertilizers such as nitrogen, phosphorus, and potassium should be accurately measured according to the formula ratio and then mixed. The mixing uniformity should reach more than 85%. An appropriate amount of binder can be added to the mixed materials as needed.

Feed granulation: The pre-treated material enters the granulation drum through the feeding device, and the water spray device sprays the material with an appropriate amount of water or binder. Driven by the transmission system, the stirring teeth rotate at high speed, vigorously stirring, impacting and turning the material, causing the material to gradually agglomerate into particles due to mutual collision and bonding.During the granulation process, the feed rate, stirring tooth speed and water spraying amount need to be adjusted according to the formation of the particles. Generally, the particle diameter can be controlled at 1-5 mm.

Screening: The finished granules are discharged from the discharging device at the end of the granulating cylinder and enter the screening equipment for screening. Unqualified granules (oversized or undersized) are separated by screens of different mesh sizes. Unqualified granules are returned to the granulating system for re-granulation, while qualified granules enter the next stage.

Drying and cooling: Granular fertilizers with high moisture content need to be dried, usually using a dryer to reduce the moisture content of the granules to below 10%.The temperature of the particles after drying is high and needs to be cooled. A cooling fan or cooler can be used to reduce the temperature of the particles to room temperature to prevent the particles from agglomerating.

Package: After cooling, the qualified granular fertilizer is measured and then packed. The packing materials can be woven bags, plastic bags, etc., which are convenient for storage and transportation.

Equipment Features

Good granulation effect: The fertilizer particles produced are highly round, uniform in size, smooth in surface, and have good fluidity. They are not easy to clump during storage and transportation, making fertilization operations easier.

Strong adaptability to materials: It can process fertilizer raw materials of various properties, especially organic raw materials with high viscosity and certain fiber content, and can achieve good granulation effect without complicated pretreatment.

Easy to operate: The equipment has a simple structure and an intuitive operation interface, and operators can become proficient in operation after simple training. During the granulation process, the granulation formation can be observed and relevant parameters can be easily adjusted to ensure granulation quality.

Lower energy consumption: Compared with some large-scale extrusion granulation equipment, the agitator granulator has lower power, lower energy consumption and relatively low operating cost, making it suitable for use by small and medium-sized fertilizer production enterprises.

Low equipment investment: The manufacturing cost of the agitator tooth granulator is low, the equipment price is relatively cheap, and the initial investment is small. For companies with limited funds, it is an economical and affordable choice.