In the field of modern organic fertilizer production, a complete bio-organic fertilizer production line is achieving a perfect transformation from raw materials to high-quality fertilizer through the collaborative innovation of key equipment.

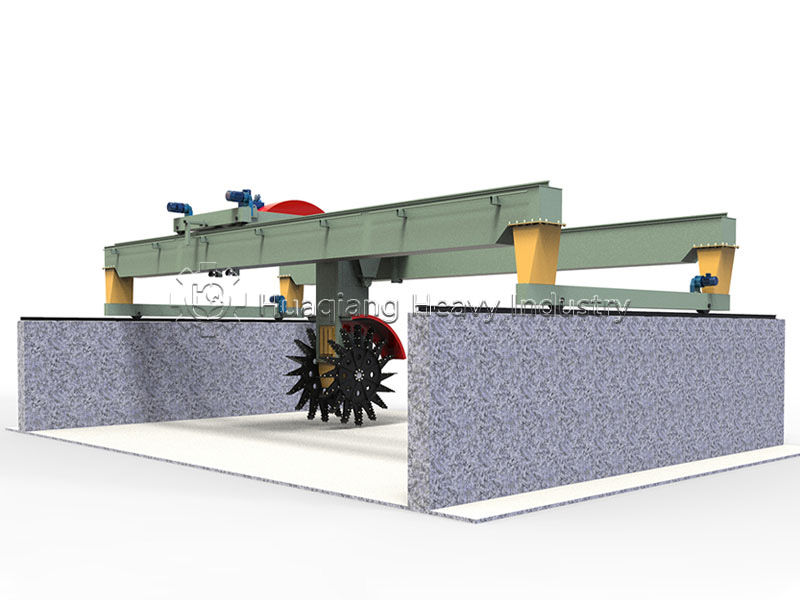

The large wheel compost turning machine demonstrates superior performance in the raw material processing stage. Its unique large-diameter turning wheel design enables deep turning of fermented materials, effectively improving oxygen exchange efficiency. This efficient turning method ensures the uniformity and thoroughness of the fermentation process, laying a solid foundation for subsequent processing stages.

Entering the core processing stage, the bio-organic fertilizer equipment system plays a crucial role. Simultaneously, the new type organic fertilizer granulator, with its innovative molding technology, transforms the fermented material into uniformly sized granular products. This granulation method not only improves the physical properties of the product but also significantly enhances its commercial value.

In the finished product deep processing stage, the fertilizer coating machine brings a qualitative leap to the product. By uniformly coating the granule surface, it not only effectively prevents product clumping but also achieves a slow-release effect of nutrients. The addition of this process significantly improves the storage stability and application effect of the final product.

As modern agriculture continues to demand higher quality organic fertilizers, this systematic production line configuration is demonstrating strong market competitiveness. It not only realizes the resource utilization of organic waste but also provides the market with higher value-added bio-organic fertilizer products through refined processing techniques, playing an increasingly important role in promoting sustainable agricultural development.