What Kind Of Raw Materials Can Huaqiang Fertilizer Granulator Process?

In modern agricultural production, the quality of fertilizer is directly related to the yield and quality of crops. As an efficient fertilizer processing equipment, Huaqiang fertilizer granulator can convert a variety of raw materials into high-quality fertilizer particles. This article will introduce the types of raw materials that Huaqiang fertilizer granulator can process and their importance in fertilizer production.

1. Processing of organic fertilizer raw materials

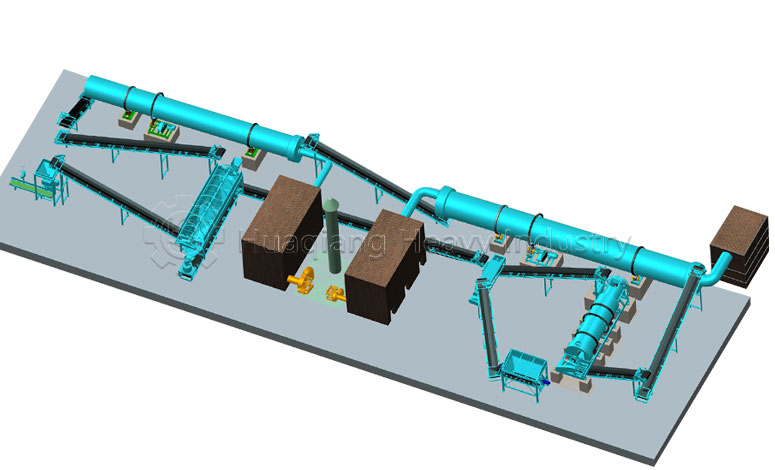

Organic fertilizer is derived from animal and plant residues, feces and other organic matter, after fermentation and decomposition of fertilizer. Huaqiang Fertilizer granulator can process these Organic raw materials and convert them into granular organic fertilizer through the Organic Fertilizer Production Line. These raw materials include but are not limited to livestock manure, crop straw, food processing waste, etc. After fermentation and granulation, they can provide soil with rich organic matter and microorganisms, improve soil structure, and improve soil fertility.

2. Conversion of chemical fertilizer raw materials

In addition to organic raw materials, Huaqiang fertilizer granulator can also process chemical fertilizer raw materials, Such as nitrogen fertilizer (Urea, Ammonium Sulfate, Ammonium Chloride), Phosphate (Ammonium Dihydrogen Phosphate, Ammonium Phosphate Dibasic, Ground Phosphate Rock and Potassium Chloride (Potassium Sulphate). These chemical Fertilizer raw materials are processed by the Fertilizer Granules Compaction Machine to form granular fertilizer suitable for agricultural production, which is easy to fertilize and improve the utilization rate of fertilizer.

3. Production of organic and inorganic compound fertilizers

Huaqiang Fertilizer granulator can also produce Organic-Inorganic Fertilizer Compound Fertilizer. This fertilizer combines the advantages of organic and chemical fertilizers to provide a variety of nutrients needed by crops while improving the soil environment. Through Bulk Blending Fertilizer Production Line, organic and inorganic raw materials are mixed evenly, and then processed into pellets by pelletizer to meet the needs of modern agriculture for efficient fertilizers.

4. Processing of high humidity materials

For high-humidity materials, such as chicken manure, Huaqiang fertilizer granulator can also be effectively treated. These materials are turned over by Windrow Compost Turning Machine after fermentation, and then processed by pelletizer, can produce high-quality organic fertilizer. This fertilizer can not only provide nutrients for plant growth, but also improve the ecological environment of the soil.

Conclusion

Huaqiang fertilizer granulator with its efficient processing capacity and a wide range of raw material adaptability, provides a strong support for fertilizer production. Whether it is organic raw materials or chemical fertilizer raw materials, it can be converted into high-quality fertilizer particles through Huaqiang granulator to meet the needs of modern agriculture for efficient and environmentally friendly fertilizers. Through scientific and reasonable processing technology, Huaqiang fertilizer granulator plays an important role in improving fertilizer quality and agricultural production efficiency.