What equipment does the 1,500 tons per month organic fertilizer Disc Granulator production line have?

In modern agricultural production, organic fertilizer has been paid more and more attention because of its environmental protection and efficient characteristics. The preparation of organic fertilizer can not only improve the soil structure, but also provide a variety of nutrient elements required for plant growth. For the large-scale production of organic fertilizers, the use of modern production lines is the key to improve efficiency and quality. This paper will introduce the main equipment involved in the production line of Disc Granulator of 1500 tons of organic fertilizer per month.

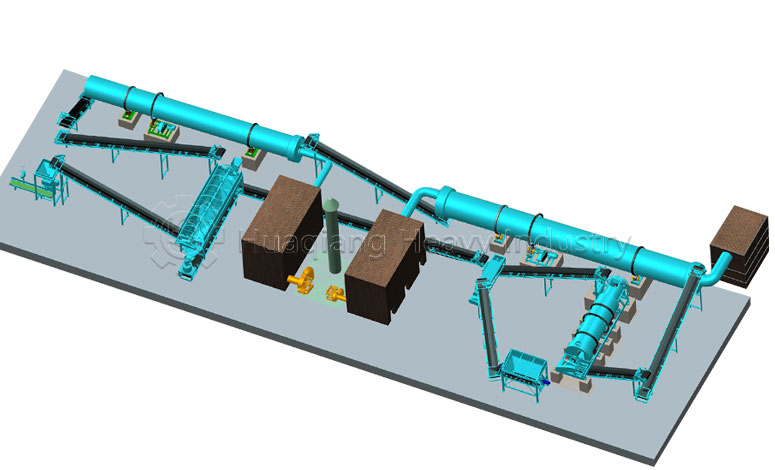

1. Organic Fertilizer Production Line

The Organic Fertilizer Production Line is the basis of the entire production process, from the pretreatment of raw materials to the packaging of the final product. In this production line, raw materials such as livestock manure, crop stalks, etc. are crushed, fermented, dried and other steps, and finally converted into organic fertilizers suitable for granulation. This process not only improves the nutritional value of the fertilizer, but also removes harmful substances that can cause pollution to the environment.

2. Disc Granulator

Disc Granulator is the core equipment in Organic Fertilizer Production Line. It distributes the material evenly on the surface of the disk by rotating disk, and makes use of the action of centrifugal force and gravity to form particles. This granulation method is not only efficient, but also can produce particles of uniform size and regular shape, which is very suitable for the production of organic fertilizer.

3. Fertilizer Granules Compaction Machine

The Fertilizer Granules Compaction Machine is another common granulation device that squeezes material with two rollers rotating in opposite directions to form particles. This equipment is especially suitable for processing materials with high water content, and can convert wet materials into dry particles in a short time, greatly improving production efficiency.

4.Windrow Compost Turning Machine

Fermentation of raw materials is a key step in the production of organic fertilizers. The Windrow Compost Turning Machine can turn the material during the fermentation process to ensure uniform fermentation of the material. This kind of equipment can effectively improve the fermentation efficiency and reduce the fermentation time by turning the pile, and also reduce the production of undesirable odors.

Through the cooperation of the above equipment, the Disc Granulator production line of 1,500 tons of organic fertilizer per month can produce high-quality organic fertilizer efficiently and stably. These devices not only improve production efficiency, but also ensure the quality of fertilizers and environmental sustainability. With the increasing demand for environmentally friendly and efficient fertilizers in modern agriculture, the applications of these devices will become more and more widespread.