Revealing the secret of oil palm high yield: How can customized compound fertilizer granulator help Southeast Asia’s Green Revolution

In the rainforests of Southeast Asia, the oil palm tree is known as the “world oil king” for its amazing oil production. However, the high yield of oil palm can not be separated from careful cultivation and scientific management, in which the use of fertilizer is particularly critical. Customized compound fertilizer granulators play a crucial role in this process.

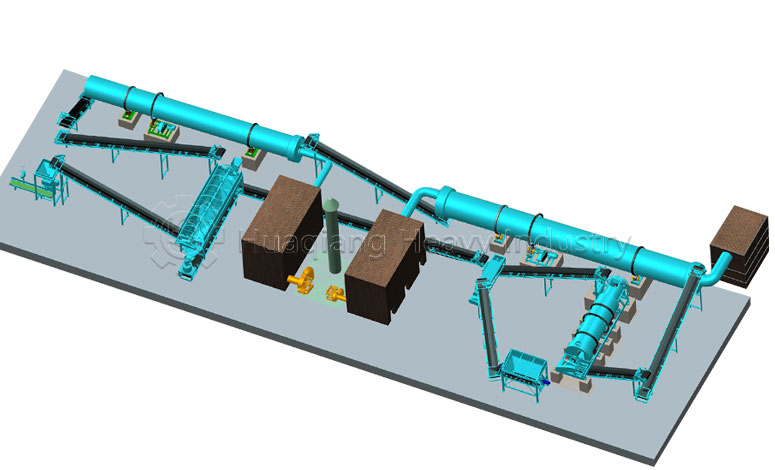

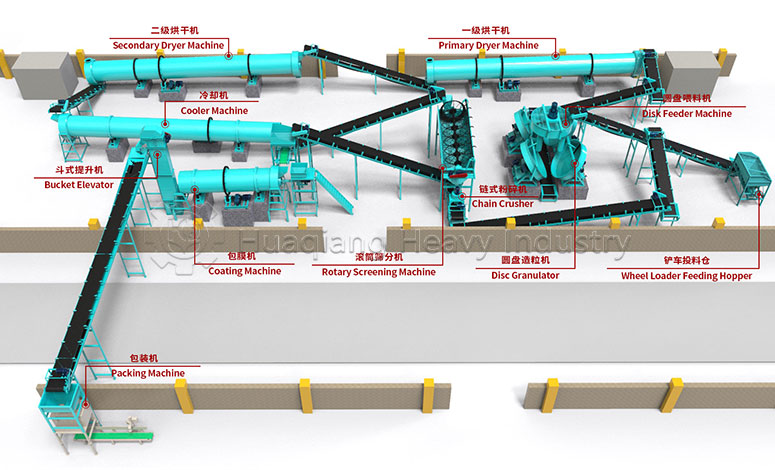

First of all, the establishment of Organic Fertilizer Production Line is the cornerstone of increasing oil palm production. Organic fertilizer can not only provide the main elements required for plant growth such as nitrogen, phosphorus and potassium, but also improve the soil structure and improve the soil’s water and fertilizer retention ability. Organic Fertilizer Production Line can be customized to produce various organic fertilizers according to the needs of different plants, which is crucial for the high yield of oil palm.

NPK Fertilizer Production Line further enriched the variety of fertilizers. This production line can meet the nutritional requirements of oil palm in different growth stages according to different proportions of nitrogen, phosphorus and potassium compound fertilizers. For example, oil palm requires higher potassium fertilizer during flower bud differentiation and more nitrogen fertilizer during fruit expansion.

Fertilizer granulator series is an indispensable part of fertilizer production line. Equipment such as Fertilizer Granules Compaction Machine and Flat-Die Pellet Machine can make fertilizer raw materials into pellets, which not only facilitates the storage and transportation of fertilizer, but also improves the utilization rate of fertilizer.

In addition, fertilizer mixers (such as the Horizontal Ribbon Mixer) also play a role in the fertilizer production process to evenly mix various raw materials, ensuring the quality and effectiveness of the fertilizer. Fertilizer Screening machines (such as Rotary screening machines) are responsible for grading the resulting fertilizer particles to ensure that the fertilizer particles are uniform in size and suitable for oil palm absorption.

Fertilizer drying and cooling machines (such as Rotary Dryer Machine and Rotary Cooler Machine) ensure that the fertilizer can quickly reduce moisture after production, improve the stability and storage life of the fertilizer.

Finally, Uniform Feeder as the front end of the production line, can evenly feed raw materials into the pelletizer, to ensure the continuity and uniformity of the production process.

Through these advanced fertilizer production equipment and technologies, the oil palm farming industry in Southeast Asia has been able to achieve a green revolution, not only increasing oil palm production, but also protecting the environment and achieving sustainable development. Customized compound Fertilizer granulators and Organic Fertilizer Production Line are helping the oil palm industry in Southeast Asia to a more prosperous future.