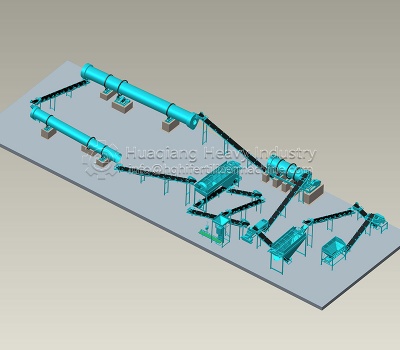

With the advancement of green agriculture and sustainable development, the problems of excessive use of chemical fertilizers in agriculture, such as environmental and soil compaction and fertility decline, have attracted attention. In this situation, bio-organic fertilizer has become a popular choice to replace traditional chemical fertilizers due to its environmental protection, safety and soil improvement characteristics. The main process of the bio-organic fertilizer production line includes the following steps:

- Raw material collection and pretreatment

Collect various organic wastes, such as livestock and poultry manure, straw, kitchen waste, fungus residue, etc. Then strictly screen the raw materials to remove impurities such as plastics and metals. Finally, pre-process the raw materials by crushing and mixing. During this process, the moisture content of the raw materials should be controlled at 50%-60%. If it is too high, straw and other auxiliary materials should be added to balance it. At the same time, pay attention to adjusting the carbon-nitrogen ratio to ensure fermentation efficiency.

- Composting and fermentation

Fermentation is the core link of bio-organic fertilizer production, which generates stable humus through the decomposition of organic matter by microorganisms. First, the raw materials are piled together, and then specific fermentation agents are added for aerobic fermentation. Then, in this process, the compost should be turned regularly by a Composting Turning Machine to increase oxygen, and the fermentation temperature should be controlled at around 65°C to kill parasite eggs and pathogens. Finally, the secondary fermentation is carried out, and after the temperature drops below 40°C, aging is carried out to promote the formation of humic acid, eliminate odor, and increase fertilizer efficiency.

- Crushing and screening

The fermented fertilizer is passed through a Drum Screener Machine to remove undecomposed crude fibers, and the fermented bulk raw materials are crushed to remove debris.

- Granulation

The fertilizer is granulated using a Disc Granulator or a Rotary Drum Granulator to improve the convenience of storage and application.

- Drying, cooling and screening

The granulated organic fertilizer granules are dried to reduce the moisture content to less than 20%. The dried granules are then cooled to room temperature and screened to select granules that meet the particle size requirements.

- Addition of microbial agents

The qualified particles after screening are evenly mixed with other additives (such as microbial agents, trace elements, etc.) to improve the nutritional comprehensiveness and biological activity of bio-organic fertilizer.

- Finished product packing

The finished bio-organic fertilizer is packed into bags or boxes using an automatic packing machine, and then sold or stored.

The above are the key steps of the bio-organic fertilizer production line. If you want to know more about this process or related equipment, please feel free to contact us.