Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

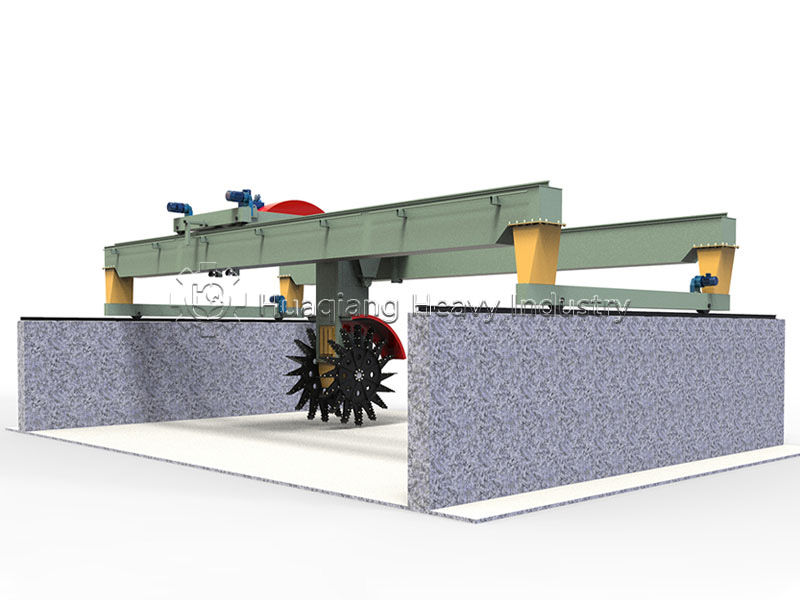

Large Wheel Compost Turning Machine

A large wheel compost turner is a material fermentation processing equipment based on a large wheel structure. Its core operating principle is that the wheel, which can reach several meters in diameter, rotates, driving turning teeth on its edge to turn the accumulated material in a circular motion. Centrifugal force and the turning teeth cause the material to be lifted, dispersed, and re-accumulated, allowing it to fully come into contact with air, regulating its temperature and humidity and accelerating microbial decomposition and ripening.

This equipment utilizes a continuously rotating large wheel design, allowing for wide coverage and high efficiency in a single turning operation. Compared to traditional trough-type or crawler-type compost turners, it is more suitable for large-scale windrow fermentation in organic fertilizer production bases with a capacity of 10,000 tons or more, significantly reducing labor and time costs for large-scale fermentation.

Equipment Structure And Composition

The main disc is the core working part of the equipment. It is welded from high-strength steel, typically with a diameter of 5-10 meters and evenly distributed turning teeth along its edge. The disc features a hollow design, reducing weight while maintaining structural strength. During operation, it rotates at a speed of 10-20 rpm, using centrifugal force to lift the material.

The turning teeth are made of wear-resistant alloy steel and are distributed spirally or radially along the edge of the disc. They are 30-60 cm long. The turning teeth are bolted to the disc for easy replacement when worn. Their optimized shape allows them to turn and disperse the material from the bottom upward during rotation, ensuring adequate contact with air.

The travel mechanism consists of a drive motor, a reducer, and travel wheels (or tracks), which are responsible for moving the entire equipment around the fermentation site. The travel wheels feature large-diameter, wide tires, resulting in low ground contact pressure and adaptability to soft surfaces. The crawler-type travel mechanism is suitable for more complex terrain, and the travel speed is adjustable via the electronic control system, typically between 0.2 and 1 m/min.

The power system consists of a wheel drive motor and a travel drive motor. The wheel drive motor, with a power of 30-75 kW, rotates the wheel through a speed reducer; the travel drive motor, with a power of 15-30 kW, provides power for machine movement. The power system can be diesel or electric, depending on site conditions, and can be equipped with a large-capacity fuel tank or cable reel.

The support structure consists of a frame and a rotating support. The frame is welded from steel sections and supports the wheel and power system. The rotating support is installed between the wheel and frame and utilizes a large bearing structure to ensure smooth rotation of the wheel and withstand the combined weight of the wheel and material (which can reach tens of tons).

The electronic control system consists of a control cabinet, an operating console, sensors, and actuators. The control panel is equipped with a touchscreen that displays real-time parameters such as the wheel rotation speed, travel speed, and machine operating time. Sensors include a temperature sensor (monitoring fermentation temperature) and a pressure sensor (monitoring wheel load). These sensors automatically generate alarms and shut down the machine for protection when abnormalities such as overload or motor overheating occur.

Auxiliary devices include a sprinkler system, lighting, and a dust cover. The sprinkler system, installed above the wheel, automatically sprays water or a microbial agent based on the moisture content of the material to adjust the humidity. The lighting facilitates nighttime operation, extending the machine’s operating time. The dust cover reduces dust raised during turning and reduces environmental pollution.

Working Principle

Raw Material Pretreatment: Bulk organic raw materials are collected and processed centrally: livestock and poultry manure is passed through a solid-liquid separator to remove excess water, reducing the moisture content to below 70%. Straw is crushed to 10-20 cm in length using a pulverizer. Industrial waste is then freed of impurities such as metal and plastic. The raw materials are mixed at a carbon-nitrogen ratio of 25-30:1, and the formula is adjusted by adding straw or manure to achieve a moisture content of 55%-60%.

Wind Stacking: Pretreated raw materials are stacked into large windrows at the composting site. The windrows are 5-8 meters wide and 1.5-2 meters high, with lengths varying depending on production (up to 100 meters). A 3-5 meter walkway is provided between windrows to facilitate movement and operation of the large-scale compost turning machine.

Turning and Fermentation: Start the large wheel compost turner and adjust the wheel height to be level with the top of the windrow. The machine moves slowly along the length of the windrow. The wheel rotates at high speed, and the turning teeth toss the material from the bottom upward. Centrifugal force causes the material to disperse to the sides and re-accumulate, ensuring thorough mixing and aeration.

During the initial fermentation period (1-3 days), the first turning of the compost is performed when the temperature reaches 50-60°C. During the high-temperature period (4-10 days), when the temperature reaches 60-70°C, the compost is turned every two days to kill pathogens. During the cooling period (11-25 days), when the temperature drops to 40-50°C, the compost is turned every three to four days to promote humus formation. The entire fermentation cycle is 20-30 days, and a single unit of equipment can turn 500-1000 tons of material per day.

Determining Compost Maturity: When the material temperature drops to near ambient temperature (±5°C), the color turns dark brown, the texture becomes loose, there is no noticeable odor, and a light earthy aroma, the material is considered mature. The mature material can be transported to the subsequent processing area by a loader for crushing, screening, and granulation.

Equipment Features

Large processing capacity and high efficiency: The large wheel diameter allows for a wide turning area per turn, capable of handling 100-200 tons of material per hour, 3-5 times that of a crawler-type compost turner. This meets the fermentation needs of large-scale organic fertilizer production and significantly shortens the fermentation cycle.

High compost turning uniformity: The centrifugal force generated by the rotating wheel ensures even material distribution, with a turning depth of up to 1.5-2 meters. This ensures thorough mixing of the upper and lower layers of the material, preventing uneven fermentation. The temperature distribution of the material varies ≤2°C, resulting in consistent composting.

Low Operating Costs: The equipment is highly automated, requiring only one or two people to operate each unit. Compared to manual compost turning or small compost turning machines, this reduces labor costs by 50%-70%. Furthermore, energy consumption per unit of material is low, and operating costs are 20%-30% lower than traditional equipment.

Suitable for Large-Scale Production: The equipment is designed for organic fertilizer production lines exceeding 10,000 tons. It can be integrated with front-end raw material pretreatment equipment (such as crushers and mixers) and back-end processing equipment (such as granulators) to form a continuous production process, meeting the demands of large-scale production.

Easy Operation: The electronic control system utilizes a touch screen interface, making parameter settings simple and enabling operators to take up the job after a short training period. The equipment operates stably, has a low failure rate, and requires minimal maintenance, making it suitable for long-term, continuous operation.