Do you know the rotary screen used in the organic fertilizer production line?

In modern agricultural production, more and more attention has been paid to the production of organic fertilizer, which can not only provide nutrients needed by plants, but also improve soil structure and soil fertility. In the production process of organic fertilizer, there is an indispensable link, that is, screening. In this process, Rotary Screening Machine plays an important role.

1. Importance of screening on Organic Fertilizer Production Line

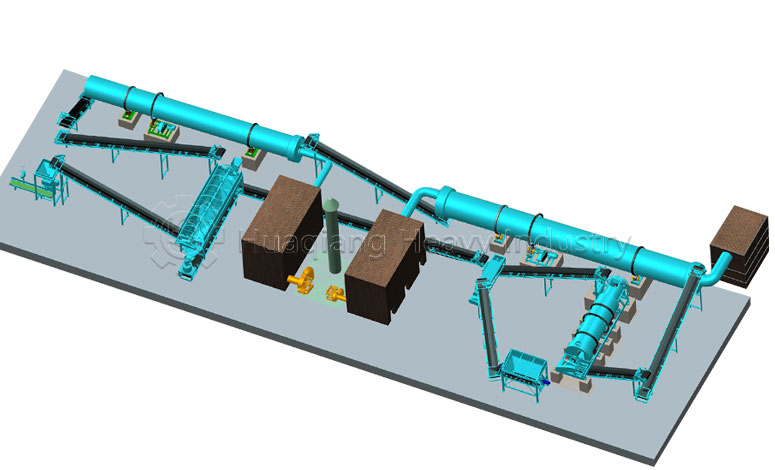

Organic Fertilizer Production Line is a complex process, it includes the collection of raw materials, fermentation, grinding, mixing, granulation, drying and packaging and other steps. In these steps, screening is a key link to ensure product quality. Through screening, impurities in raw materials can be removed to ensure the purity of fertilizer, while fertilizer particles can also be graded to meet the needs of different crops.

2. Working principle of Rotary Screening Machine

Rotary Screening Machine is a commonly used screening equipment in Organic Fertilizer Production Line. It uses a rotating drum to grade the material using a screen. The material enters the drum from the feed end, and under the rotating action of the drum, the smaller particles fall through the screen, while the larger particles are discharged from the discharge end. This equipment has the advantages of simple structure, convenient operation and high screening efficiency, which is very suitable for the screening work of organic fertilizer.

3. Advantages of Rotary Screening Machine

Rotary Screening machines offer many advantages over traditional screening machines. First of all, its high screening accuracy can effectively remove impurities and unqualified particles in the material. Secondly, the Rotary Screening Machine has stable operation, low maintenance cost, and is suitable for long-term continuous operation. In addition, the Rotary Screening Machine’s compact design and small footprint make it ideal for the layout requirements of organic fertilizer production lines.

4. Application of screening machine in organic fertilizer production

In the production process of organic fertilizer, the screening machine is not only used for the screening of the final product, but also for the treatment of raw materials. For example, when processing raw materials such as livestock manure and crop straw, the screening machine can remove large impurities in it to ensure the smooth progress of subsequent fermentation and granulation process. In addition, the screening machine can also be used for the pre-packaging treatment of organic fertilizer to ensure that the packaged fertilizer particles are uniform and improve the market competitiveness of the product.

Conclusion

From the above introduction, we can see that Rotary Screening Machine plays an important role in Organic Fertilizer Production Line. It not only improves the production efficiency of fertilizer, but also ensures the quality of fertilizer, and is one of the indispensable equipment in the production of organic fertilizer. With the continuous expansion of the organic fertilizer market, the application of Rotary Screening machines will be more and more extensive.