In the production of powdered fertilizers, the efficiency of the fermentation process and the quality of raw material decomposition directly determine the pace of subsequent processing. As a core production auxiliary equipment, compost turning machines improve overall production efficiency from multiple key points by optimizing the fermentation process, improving raw material characteristics, and connecting production processes.

Accelerating raw material decomposition. Powdered fertilizer raw materials are mostly organic materials such as livestock and poultry manure and crop straw. Natural fermentation cycles are long and prone to uneven decomposition. Compost turners, through deep turning and mixing, can quickly break up material clumps, allowing the material to fully contact the air, increasing microbial activity, and promoting the rapid decomposition of organic matter.

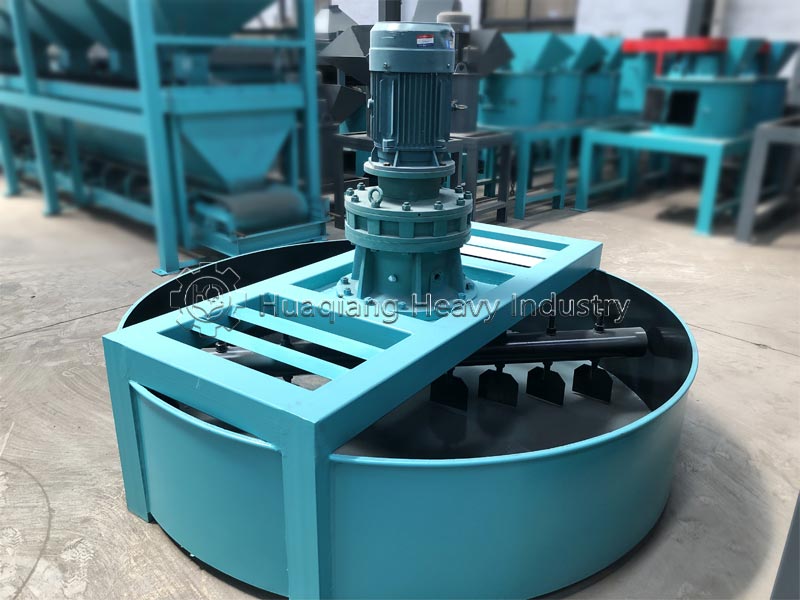

Optimizing raw material characteristics. During the turning process, the compost turning machine can simultaneously mix and crush the materials, reducing clumping and resulting in more uniform particle size of the decomposed raw materials, eliminating the need for additional crushing and screening processes. This pre-treatment optimization makes the raw materials more suitable for subsequent grinding and fertilizer mixing equipment for powdered fertilizers, preventing equipment blockage or processing difficulties, improving the processing efficiency of subsequent processes, and reducing energy consumption and material loss.

Ensuring continuous production. Compost turners can achieve continuous and large-scale operation without frequent shutdowns for adjustments, stably supplying qualified raw materials to subsequent processes and avoiding production interruptions due to raw material shortages. At the same time, its flexible operating mode can adapt to different scales of production needs, ensuring smooth production flow whether in small and medium-sized decentralized production or large-scale fertilizer production lines.